QUALIFICATION & VALIDATION for Cleanrooms and Contamination-Controlled Environments

Comprehensive solutions for each stage of the contamination control process.

You can count on our highly trained expert team with customized, comprehensive contamination control solutions.

Our qualified validation engineers from ICS conduct thorough environmental performance validation for cleanrooms, safety cabinets, surgery rooms, IVF rooms, electronic production areas, Local Exhaust Ventilation (LEV) systems, and workstations. Beyond ensuring initial compliance, we also guarantee continued adherence to all necessary standards, industry guidelines, and cGMPs.

Link Lab is an ESYD ISO17025 certified testing laboratory (Lab No. 254).

Our validation services provide assurance that your clean air facilities and equipment meet national standards and industry guidelines.

- Air velocity and air volume flow rate measurement

- Pressure differential measurement

- HEPA filter installation integrity leak testing (photometer or particle counter scanning)

- Airborne particle cleanliness classification (counts)

- Air quality tests

- Recovery rates

- Airflow visualisation studies

- Induction leak testing

- Temperature and relative humidity measurement and mapping

- System inspections

- Lighting and noise measurements

- Aperture retention (operator protection) tests

- Microbiological sampling (active air, settle and contact plates)

Our engineers are experienced with a wide range of clean air applications, from single clean air cabinets to the largest ISO Class 5 cleanroom in Europe.

When air cleanliness is critical, our unmatched expertise allows us to offer a comprehensive range of testing and monitoring services for essential clean air facilities and equipment. All tests are conducted in accordance with international standards, including ISO 14644 Parts 1, 2, 3, 4, and 7, EN 12469, and the EU GMP Annex 1 guidelines.

- Cleanrooms

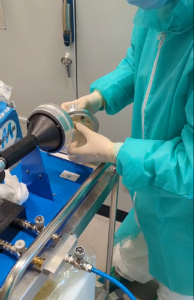

- Pharmaceutical Isolators & RABs

- Unidirectional Flow Workstations

- Microbiological Safety Cabinets (Classes I, II and III)

- IVF Clean Laboratories

- Surgery rooms, Operation theaters

- Electronic production rooms

- Sampling and Weighting booths

- Negative Pressure Isolators

- Ducted Fume Cupboards

- Gene Therapy Cleanroom

LEV Testing & Fume Cupboards

Workplace safety is crucial and Local Exhaust Ventilation (LEV) systems, along with fume cupboards, play a critical role in manufacturing environments. Dust, hazardous particles, and chemical fumes ca n pose significant health risks to employees. Even if these risks appear minor, prolonged exposure can lead to severe and irreversible health issues.Equally important is the routine testing and assessment of these systems to ensure they continue to provide adequate protection for workers.In compliance with the COSHH (Control of Substances Hazardous to Health) regulations, LEV systems are required to undergo regular testing by a qualified and competent professional.

We offer comprehensive inspections and testing services to ensure your LEV systems and fume cupboards meet the highest safety standards.

- Local Exhaust Ventilation Systems (LEV)

- Capture Hoods and Workstations

- Ducted and Recirculatory Fume Cupboards

- Safety cabinets and negative pressure isolators can also be considered LEV equipment.

All of this testing provides the assurance that health & safety is suitably addressed.

To ensure the safety of the patients and Hospital Trusts, we offer a comprehensive verification service for ventilation systems serving:

- Surgery theaters

- Cytotoxic chambers and isolators

- Pharmacy & Radiopharmacy Cleanrooms

- IVF Suites

We provide specialized air quality testing for compressed gases used in cleanrooms, ensuring that the quality of the supply air does not affect the cleanliness, product integrity, or processes. Our testing covers key contaminants such as particles, oil, moisture and microbials, in line with industry standards.

Testing is performed in compliance with BS EN ISO 8573, and the European Pharmacopoeia.

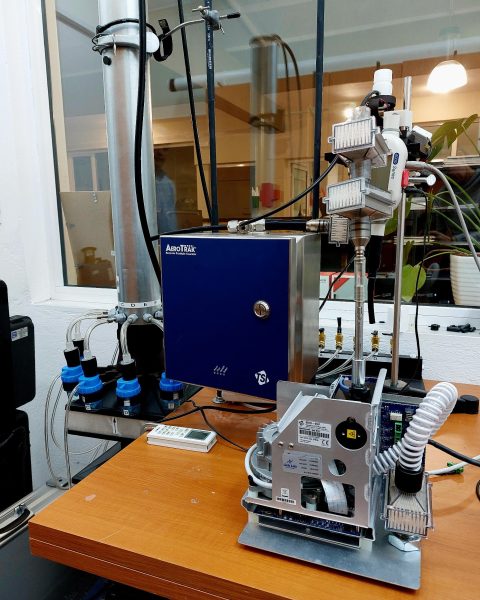

Particle Counter Calibration acc ISO 21501-4 : 2018

Link Lab Ltd provides a high standard of service. This is achieved by having a fully equipped facility based in Athens to support our customers in Greece , Cyprus and near countries.

Aerosol particle counters must undergo calibration in accordance with the stringent requirements of ISO 21501-4:2018, which involves verifying and adjusting particle sizing, resolution, counting efficiency, flow rate, signal ratios, and zero count. Each calibration is performed using NIST-traceable standards, and a calibration certificate is issued for every calibration.

Our services are as follows:

- In-House Particle Counter Calibrations

- Particle Counter Calibration to ISO 21501-4 (on compliant particle counters)

- In-House calibration on Air Samplers

- In-House calibration of anemometers, differential manometers, temperature and humidity sensors

- Traceable reference units for Aerosol particle counters

Particle Counter Calibration includes:

- Particle counter adjustments back to factory standards

- Certificate of calibration issued for each instrument

- Preventative maintenance

- Instrument condition (as found and as left data available)

- NIST traceable standards